Both digital cylinders and servo cylinders are cylinders that focus on control. Some friends think that digital cylinders are servo cylinders, but they are not. Although digital cylinders can also be controlled by servo motors, they are very different from servo cylinders, and because of their unique advantages, they have become an iterative upgrade product of servo cylinders.

1. The structure of the digital cylinder is simple

The servo cylinder system is generally composed of individual components such as cylinder block, servo valve, grating ruler, A/D+D/A module and so on. This structure has unavoidable defects:

The parts are scattered, easily damaged and lost;

The external sensor has poor protection and is easy to be damaged and drift due to external interference, thus affecting accuracy;

Many external connection points affect the response speed and destroy the overall beauty of the equipment;

Sensors such as grating rulers emit radiation, and exposure to the outside is harmful to the environment and human health.

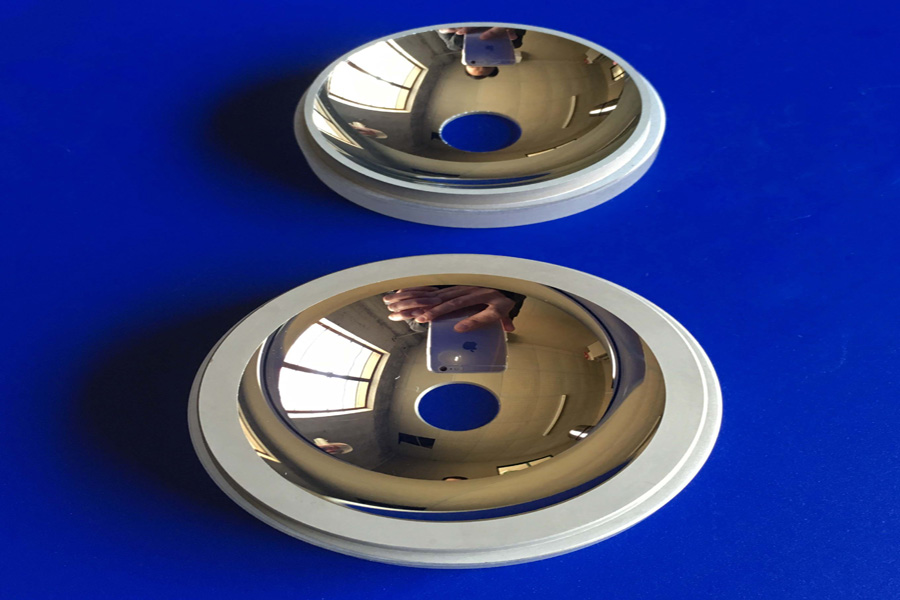

In contrast, the structure of the digital cylinder is much simpler. It integrates the cylinder block, digital valve, feedback system and input servo motor into a whole, only the control system is independent. However, due to the high concentration of components, the digital cylinder cannot be too miniaturized.

2. The same control method and target

The digital cylinder system and the servo cylinder can be controlled by conventional PLC/touch screen, or by a dedicated numerical control system. The purpose of both is to be used for location positioning, precise displacement, direction, speed, pressure and other indicators. However, the digital oil cylinder is faster and more intuitive than the servo oil cylinder when adjusting the execution program, and it is easier for the user to master the programming and adjustment methods. In addition, in terms of control accuracy, the digital cylinder system and the servo cylinder system are basically at the same level, but the response speed of the digital cylinder is more advantageous than the servo cylinder.

Third, the digital cylinder is more cost-effective

In terms of cost performance, the advantages of digital cylinders are much higher than those of servo cylinders, which are embodied in these aspects:

The unit price of digital cylinders is basically the same as that of servo cylinders or slightly higher than that of servo cylinders. However, the use cost of digital cylinders is very low and can basically be in a maintenance-free state, while the use cost of servo cylinders is higher;

Digital cylinders have low requirements for oil cleanliness, and only need a conventional filter system. Servo cylinders have extremely high requirements for oil products, not only need a precision filter system, but the oil needs to be replaced frequently;

When the digital cylinder fails, it can basically be repaired in time on site, and the zero can be automatically adjusted after repair; if the servo cylinder is faulty, it must be returned to the factory for repair and the servo valve must be zeroed on the calibration station. The repair cycle is long and the maintenance cost is high;

The digital oil cylinder has a high degree of integration and good parts interchangeability; the servo oil cylinder is a single-piece layout, and the parts interchangeability is poor and prone to matching errors.

With the same performance and function of the servo cylinder, it also has the unmatched advantages of the servo cylinder in terms of structure, cost performance, operability, etc., and it is logical that the digital cylinder is an iterative upgrade product of the servo cylinder. Now, digital oil cylinders have been applied in many fields such as industry, aerospace, medical treatment, home appliances, etc., and have been widely praised by customers.