How About The Spinning Process In Japan?

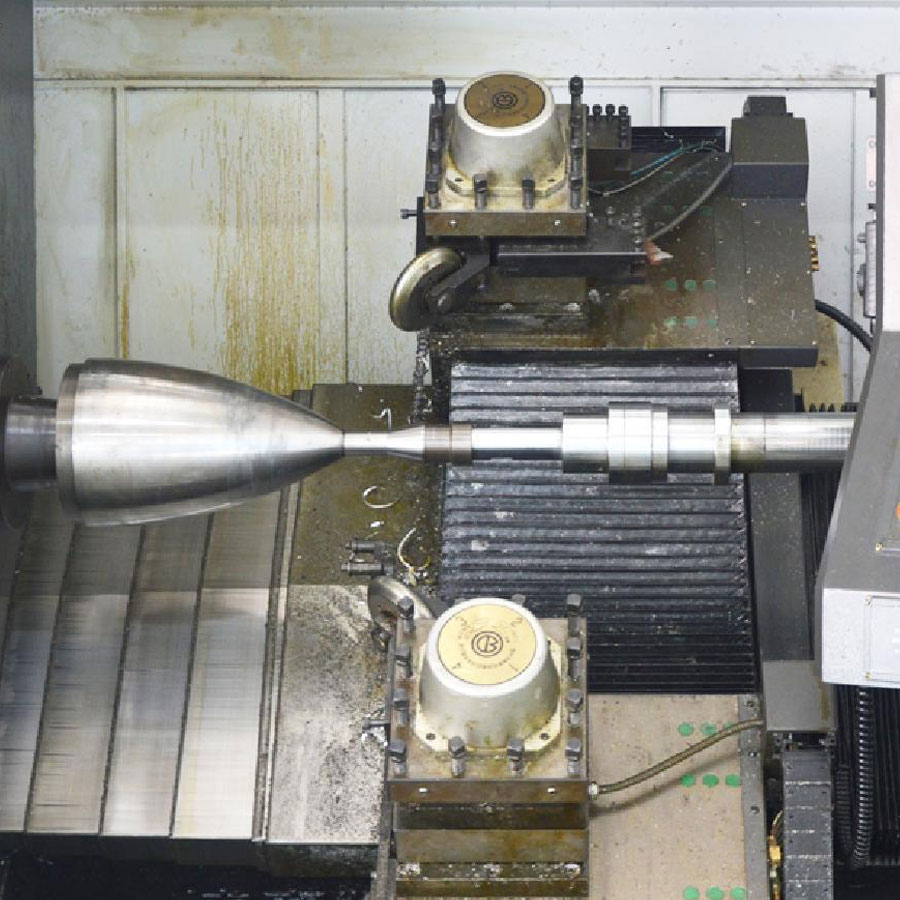

The spinning process is a process in which the metal plate in the high-speed rotation close to the mold is pressed with a strip-shaped tool

Wonder Metal offers one shop for all your production metal spinning parts and aluminum reflector. We produce quality spinning parts, sheet metal fabricating, metal stamping prototypes and production, fiber laser cutting, tool and die making and related services.

As a leading China Metal Spinning company, aluminum spinning products are the specialty of Wonder Metal. We excel in manufacturing high precision, high production custom metal spinning parts and aluminum reflector to meet ISO 9001:2015 certification. Our machine shop services include aluminum spinning, copper spinning, steel spinning and more.

WONDER SPINNING METAL PRODUCT COMPANY was founded in 2004, located in the top of China hundred counties– Dongguan Humen City, Guangdong And ZhongShan. The company factory covers an area of over 8,000 square meters, and there are currently 100 employees. The company’s products mainly involve a wide range of uses. For instance, we supply all kinds of ventilation equipment and the outlet of buildings, aviation accessories, auto parts, lamp series, heating series, and etc. Our company had also participated the production supporting services of venue outlet in the Games of the Beijing Olympiad in 2008 at National Stadium, what is so called “Bird Nest”, the Water Cube, and China Pavilion at Expo 2010 Shanghai China, and we got the customers’ unanimous approval. In this highly competitive market, we insist on providing quality service by maintaining a strict standard. Thus enabling customers to enjoy our high quality products and services with superb technology and reasonable prices.

“Our Vision is to provide premier, small metal spinning part production machining services to our customers while providing a high Quality of Life for our employees and being a positive influence.”

This is a bold statement that we sincerely strive to live up to – we do not claim to be perfect, but we do stand committed. We feel these three objectives are interrelated and interdependent. And, we feel our “Core Values” of “Team Work”, “Continuous Improvement”, and “Perseverance” are central to living up to these objectives.

Highly skilled people are at the heart of Wonder Metal’ success, and they make our company unique in the industry. From our tool room staff to Metal Spinning operators, our employees are cross-trained to support different areas based on workload so we can maintain workflow. You can count on our talented people to produce some of the highest quality metal spinning parts in the world.

Wonder Metal Company founded in 2004. In our first 10 years, we had the opportunity to listen to our customers, provide solutions and grow our business. we Expanded our plant and add advanced machines to reflect our diverse services. Our ownership, management team, and highly skilled people have remained through the years.

Wonder specializes in custom CNC aluminum spinning, copper spinning and stainless steel spinning. The core advantages are large thickness, good precision, and the overall finished product process. The company has independently designed and assembled special spinning equipment, 8 years of metal spinning forming technology, the company can now process spinning parts with a diameter range of 50-1200mm, a length range of 500mm, and a processing material thickness range of stainless steel 0.5-3mm. Iron 0.8-4mm, aluminum 0.8-7mm. Rich experience in various product projects. The products that have been successfully produced include venturi, venturi valve, three-way catalytic converter, aluminum barrel, milk barrel, electrical liner, titanium alloy tableware, shielding cover, signal transmitting and receiving cover, fan Tuyere/current collector/diversion ring, communication cover, stainless steel funnel, automobile shock absorber shell, copper hot pot, seal head, etc., have manufactured high-quality spinning products for many domestic manufacturers.

Wonder takes spinning processing as its core business, and has 3D laser cutting, 3D laser welding, argon arc welding and other supporting technologies. It has strong comprehensive production capabilities for spinning products and provides customers with competitive products.

Wonder has accumulated 15 years of CNC spinning technology, and has excellent CNC spinning process and special equipment design capabilities. It solves the difficult spinning forming projects in the market. The company focuses on aluminum Reflector spinning, stainless steel spinning, high-thickness and high-precision metal spinning. , The company has 6 technicians, and the plant covers an area of 1,200 square meters. Dingchuang is committed to spinning processing with the spirit of “focusing on innovation”, continuously improving process technology and increasing efficiency, and working hand in hand with customers on the principle of “integrity-based, mutual benefit and win-win”. Strive to create more perfect spinning products to give back to customers.

Wonder’ modern manufacturing facilities total approximately 8000 square meter. We have taken the same care in the design and maintenance of our facilities as we do with the equipment and parts we build. This has resulted in efficient work flow, a safe and comfortable working environment for our valued employees, and plenty of room for additional growth.

The spinning process is a process in which the metal plate in the high-speed rotation close to the mold is pressed with a strip-shaped tool

Aluminum high bay light spining lampshade Aluminum spining light cover lampshade The product is applied to the LED lamp shell for high bay light. The material of spining can be steel…

High Quality Mirror Aluminium Reflector for LED High Bay Light aluminum reflector of high bay lighthigh quality mirror aluminium reflector custom aluminum led reflector

Aluminum high bay light spining lampshade Aluminum spining light cover lampshade The product is applied to the LED lamp shell for high bay light. The material of spining can be steel…

Aluminum high bay light spining lampshade Aluminum spining light cover lampshade The product is applied to the LED lamp shell for high bay light. The material of spining can be steel…

Aluminum high bay light spining lampshade Aluminum spining light cover lampshade The product is applied to the LED lamp shell for high bay light. The material of spining can be steel…

If you are looking for Metal Spinning China, Wonder Metal Inc is ready to give them to you! With us, you will have the opportunity to make your custom spinning parts, aluminum reflector,prototype production easy and less hassle. If you want to avail our service, call us now and get a metal spinning quote!

Want some help getting your aluminum reflector, heatsink or other led lighting parts order ready? Download our reflector, heatsink,housing order sheet. Fill in what you need. Send it back to [email protected].

You already know what exactly you want? Just send us an email by using the email form on the right.

No 3,Zhengda Road,Shatou Village,Chang’an Town,Dongguan City,Guangdong Province,China | Copyright © Dongguan Wonder Metal Co., Ltd. All Rights Reserved.