Application of CNC machining technology in the automotive industry

The traditional automobile industry usually pursues efficiency and scale. At present, society has put forward higher requirements for automobile functions, requiring good overall performance of the automobile, and relatively good accuracy of parts and components. Under the background of the current era, CNC technology should be strengthened. Application, numerical control technology can promote the rapid development of automobile processing enterprises in the direction of small-scale, personalized and high-efficiency. Through the use of numerical control technology, it can also carry out rapid processing of automobile cylinders, connecting rods, piston crankshafts and other parts. In addition, stamping In the process of, painting, welding, etc., the use of CNC machine tools should be strengthened. Workers need to combine many elements such as industrial robots and numerical control machine tools with computers to realize a flexible manufacturing system to improve work quality and work efficiency. At present, most automobile companies use numerical control technology for automobile manufacturing. By using robots, work efficiency and work quality can be improved, and the work safety of workers can be guaranteed.

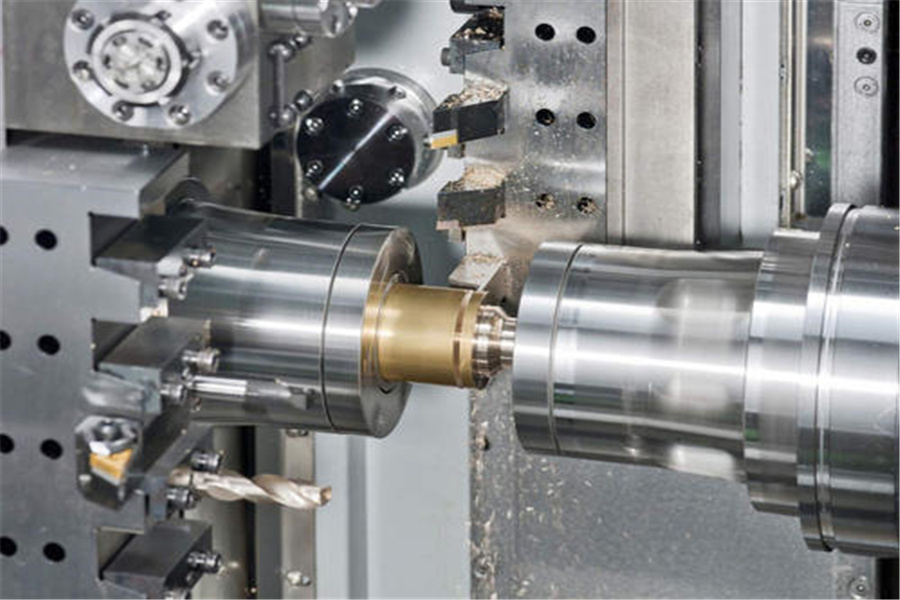

2 Application of CNC machining technology in coal mining machinery

Numerical control technology can be fully used in the process of coal mining machinery. In the process of coal mining machinery manufacturing, it usually requires cutting and blank manufacturing processes. In this process, CNC technology can be fully utilized. Effective adjustment of process parameters can also realize intelligent manufacturing, promote the overall improvement of operation efficiency and production quality, and promote the overall improvement of mechanical performance, without the participation of staff, effectively reducing the risk of personnel. In the process of processing the floating oil seal structure of the shearer, the staff should ensure that the compression of the sealing ring is equal between the protruding surface of the inner ring and the concave surface of the outer ring. In this process, the CNC cutting technology can be used to promote cutting The speed is faster, and the precision of the processing can be guaranteed.

3 Application of CNC machining technology in aerospace

Aerospace technology is an important symbol of the development of science and technology in China, and an important manifestation of the improvement of comprehensive national strength. Aerospace technology needs to pay more attention to accuracy. In aerospace equipment, a variety of lightweight materials are generally used, such as titanium alloys, aluminum alloys, etc. If the traditional method is used for cutting titanium alloy and aluminum alloy, it is easy to cause deformation of parts and components, which will have a greater negative impact on the accuracy of processing and the overall quality. However, in the process of aerospace equipment manufacturing Among them, through the use of numerical control technology combined with high-speed mechanical technology, not only does it produce less heat, but at the same time the cutting speed is fast and the quality is high. In addition, numerical control technology, fuzzy control technology, artificial neural network technology, etc. are integrated with each other, which can realize dynamic processing, promote the overall improvement of processing accuracy, and meet the needs of aerospace equipment.

4 Application of CNC machining technology in industrial production

In the process of industrial production, the application of numerical control technology can be strengthened. The typical application of numerical control technology is industrial robots. Industrial robots can quickly accept human instructions and can work according to set procedures. Industrial robots are generally used in welding and industrial Handling, machining, spraying and assembly, and many other production links, by using industrial robots to replace humans, it is possible to work in harmful, toxic, and high-temperature environments. This avoids the danger of working in these harsh environments among workers. In addition, Industrial robots include many key technologies, such as high-speed performance controllers, high-performance servo motors, and precision reducers. Industrial robots are mainly controlled by computer technology, and the control panel drives to complete operations, which effectively guarantees production. Safety and reliability, while also improving product quality and production efficiency.

One-stop machining cloud platform to speed up the network, parts processing So Easy!