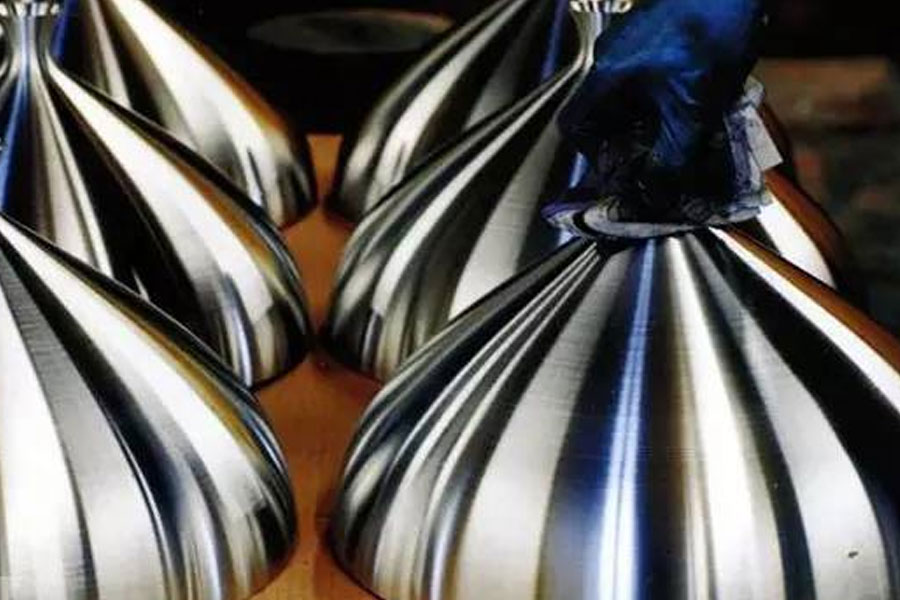

During the spinning process, the head is transformed from a flat round plate blank into an elliptical head. The round plate blank is compressed in the circumferential direction and stretched in the radial direction, but it is different from the drawing process. There is basically a point contact between the roller and the blank, and the blank produces two kinds of deformation under the action of the roller: one is the local plastic deformation of the material in direct contact with the roller; the other is that the blank falls in the direction of the pressure of the roller .

It is very important to control the roller during operation. Improper operation can cause material instability, wrinkling, shaking or tearing. When spinning, it is important to choose a reasonable spindle speed, the transition shape of the shape and the size of the roller pressure. If the spindle speed is too low, the blank will be unstable;

If the rotation speed is too high, the contact between the material and the roller is too frequent, and it is easy to over-thin; the reasonable rotation speed is related to the material type, thickness and core die diameter. When the blank diameter is larger and the thickness is small, the rotation speed can be smaller, and vice versa. Big.

Advantages and limitations often complement each other. What are the limitations of CNC spinning manufacturers in advance? Have a better understanding of this limitation in advance, so that you can formulate a suitable production plan to a certain extent and truly ensure that the final production can be completed smoothly.

On the one hand, the effective efficiency of CNC spinning manufacturers in the entire processing process is relatively low. This will have a lot of constraints on mass production. Only when we recognize this problem in a targeted manner and consider the constraints in this area before production, can we better realize our own production.

On the other hand, the metal spinning process requires a relatively large labor force. When the work intensity is high, it will inevitably cause problems in all aspects. We must actively address all aspects of stainless steel spinning. Good understanding and understanding, these limitations also need us to change bit by bit in the future.